DSG Series - Liquid line Filter Drier with Sight Glass DSG Series - Liquid line Filter Drier with Sight Glass

DSG

Series liquid line filter drier/sight glass combination is a liquid line filter

drier with a sight glass connected to the outlet

side of the filter drier are used in refrigeration system

with unidirectional flow to absorb moisture in the system and to filter

out the impurities.

Observe property changes of the refrigerant (liquid / vapor) and indicate the

moisture level by the sight glass as well

Technical parameters

-

Features

- Highly efficient in moisture absorption, filtering impurity, paint remains and mud

removal

- Durable and solid filter cores

- Filtering fineness: 20μm

- Corrosion resistant painting survives salt spray test of 500 hours

- Sight glass with new annular humidity color indicator to realize high precision and full port passage with low pressure drop

- Compact unit: reduce customer installation time and reduce potential leakage risk

-

General Specification

- Applicable for all common HFC, HFO refrigerants such as: R134a, R404A, R407A/F, R407C, R410A, R448A, R449A, R450A, R452A, R513A, R507A

- Ambient temperature min./max.: -30°C / +55°C

- Medium temperature TS min./max.: -30°C / +80°C

- Max. operating pressure PS max.: 4,6 MPa

- Installation position: - Flow direction corresponds to the arrow

- Preferably installed in liquid line

- Certifications: UL/CSA and PED declaration

Technical Parameters

Desiccant Selection Table

Medium type

100% 3Å desiccant

Refrigerant

HFC

Applicable

HFO

Applicable

Oil

Mineral oil or AB

Applicable

Pure POE or PAG

Applicable

POE or PAG with additive

Applicable

-

Model Designation Legend

Model Designation Legend

1

Product Code

Product Series

DSG

Indicates unidirectional filter drier with Sight glass

2

Filter Core

Structure and Material

B

Compact core, 100%3Å desiccant

3

Internal Volume¹⁾

Expressed in [ inch3 ]

Expressed in [ cm3 ]

05

5

82

08

8

131

16

16

262

4

Connection Size

Pos. 5 shows "4": SAE Flare [inch]

02

1/4

03

3/8

04

1/2

5

Pipe Connection

Type

4

SAE flare connections

6

Version Number

Description

002

Series number

Model Designation Example:

Position Number

According to Model Designation Legend

1

2

3

4

5

6

DSG

B

05

02

4

002

Unidirectional filter drier & sight glass assembly

DSG

B

05

02

4

002

Solid filter core with 100% 3Å desiccant

DSG

B

05

02

4

002

5 inch3 internal volume

DSG

B

05

02

4

002

When Pos. 5 is “4”: SAE flare connection size 1/4”

DSG

B

05

02

4

002

SAE flare connection

DSG

B

05

02

4

002

Series number

-

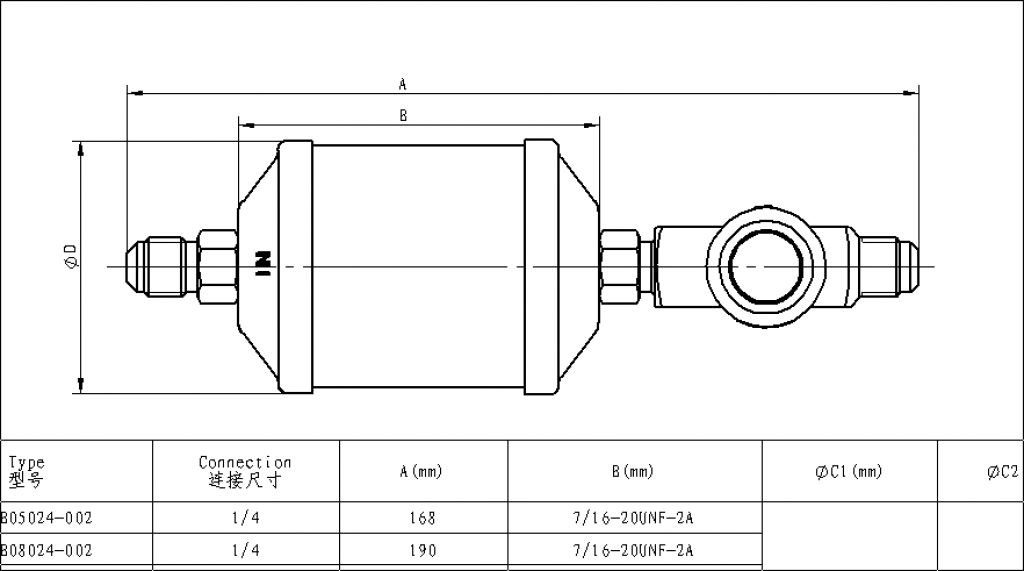

Version with male/male Flare connections

Version with male/male Flare connections

Series

Model

Part Number1)

Nominal Volume

Connection

Dimensions & Weight

PED

Category²⁾

SAE Flare

ØD

A

B

Weight

[inch³]

[cm3]

[inch]

[mm]

[mm]

[mm]

[ g ]

DSGB 052

DSG-B05 024-002

10221000102

5

82

1/4

69

168

76

620

Art. 4.3

DSGB 082

DSG-B08 024-002

10221000202

8

131

1/4

69

190

89

640

Art. 4.3

DSGB 083

DSG-B08 034-002

10221000302

8

131

3/8

69

214

89

640

Art. 4.3

DSGB 163

DSG-B16 034-002

10221000402

16

262

3/8

69

234

118

700

Art. 4.3

DSGB 164

DSG-B16 044-002

10221000502

16

262

1/2

69

245

118

700

Art. 4.3

Note:

- Available also as industrial package. Contact Sanhua for more details.

2) PED Directive 2014/68/EU

-

Selection Table

Selection Table

Series

Capacity¹⁾ [kW]

Moisture Absorption (gram H2O)

R134a

R404A

R22

R407C²⁾

R410A

R134a

R404A

R407C²⁾

R22

R507A

R410A

R507A

75°F

125°F

75°F

125°F

75°F

125°F

75°F

125°F

23,9°C

51,7°C

23,9°C

51,7°C

23,9°C

51,7°C

23,9°C

51,7°C

DSGB 052

8,4

6,0

8,4

8,4

8,4

11,6

10,9

10,9

8,9

10,9

9,5

11,4

9,7

DSGB 082

8,4

6,0

8,4

8,4

8,4

14,8

14,2

16,3

13,4

14,8

13,0

15,5

13,1

DSGB 083

25,0

17,6

25,3

25,0

25,7

14,8

14,2

16,3

13,4

14,8

13,0

15,5

13,1

DSGB 163

25,7

17,9

26,0

26,0

26,4

20,6

19,5

33,2

18,3

20,6

17,6

20,9

17,7

DSGB 164

32,4

22,9

33,1

32,7

33,8

20,6

19,5

33,2

18,3

20,6

17,6

20,9

17,7

Note:

- the above data is based on clean system at ideal conditions; with impurities accumulated in the filter, the capacity may decrease

- R407C capacity is based on dew point conditions

Selection Formulas:

Filter Driers for liquid line are manufactured in compliance with ARI Standard 710. Maximum flow rate of liquid refrigerant at a differential pressure of 0,07bar (1psi) is indicated by kW (ton) which is based on the temperature of liquid refrigerant 30°C (86°F), the evaporating temperature of

-15°C (5°F) and the following mass flow:

• 0,40 kg/min/kW (3.1 lb/min/ton) R134a

• 0,53 kg/min/kW (4.1 lb/min/ton) R404A, R507A

• 0,39 kg/min/kW (3.0 lb/min/ton) R22, R407C

• 0,36 kg/min/kW (2.8 lb/min/ton) R410A

Note: Data on water absorption is based on the following EPD (method: ASHRAE Standard 63.1):

• 60ppm R22

• 50ppm R134a

• 50ppm R404A

• 50ppm R407C

• 50ppm R410A

• 50ppm R507A

Moisture Indication Limits :

Refrigerant

Moisture Content 25°C: PPM

Green/Dry

Middle Color

Yellow/Wet

R22

<100

100~200

>200

R134a

Download Full Technical Information

Need even more detail or going offline? Find here all the technical specifications and product data.

Datasheet Instructions Declaration of Conformity EU Declaration of Conformity UK